①單季度來看,2024Q2公司淨利潤和扣非歸母淨利潤均創歷史新高;②半導體市場需求回暖,公司緊抓行業發展機遇,整體業務收入同比增長,產品結構進一步優化,高階品佔比提升,利潤同比獲得增長。

《科創板日報》8月26日訊(記者 吳旭光)8月25日晚間,硅微粉龍頭聯瑞新材披露2024年半年報。

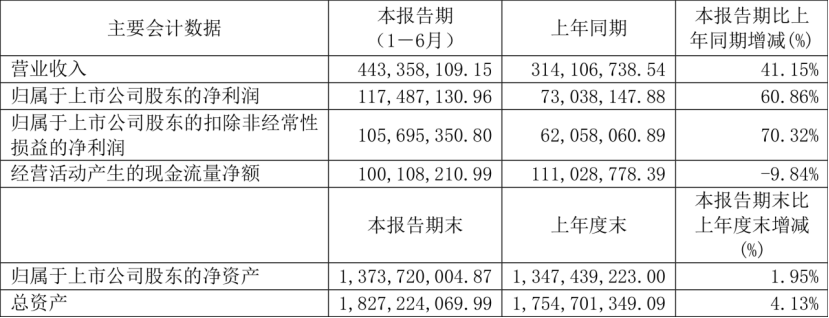

2024年上半年,聯瑞新材實現營業總收入4.43億元,同比增長41.15%;歸母淨利潤1.17億元,同比增長60.86%;扣非歸母淨利潤1.06億元,同比增長70.32%;經營活動產生的現金流量淨額爲1.00億元,同比下降9.84%。

單季度來看,2024Q2公司淨利潤和扣非歸母淨利潤均創歷史新高。

單季度來看,2024Q2公司淨利潤和扣非歸母淨利潤均創歷史新高。

聯瑞新材二季度實現歸母淨利潤0.66億元,環比增加27.36%;扣非歸母淨利潤0.60億元,環比增加32.02%。

對於業績變化,聯瑞新材表示,報告期內,半導體市場需求回暖,公司緊抓行業發展機遇,整體業務收入同比增長,產品結構進一步優化,高階品佔比提升,利潤同比獲得增長。

聯瑞新材主要業務涉及無機填料和顆粒載體行業產品的研發、製造和銷售,公司硅微粉產品主要分爲角型硅微粉和球形硅微粉兩大類,其中包括有結晶硅微粉、熔融硅微粉、球形硅微粉、球形氧化鋁粉以及氮化物等粉體材料,應用於芯片封裝用環氧塑封料、電子電路基板、熱界面材料、特種蜂窩陶瓷載體、3D打印材料等領域。

聯瑞新材表示,報告期內,公司聚焦高端芯片(AI、5G、HPC等)封裝 、異構集成先進封裝(Chiplet、HBM等)、新一代高頻高速覆銅板(M7、M8 等)、新能源汽車用高導熱熱界面材料等下游應用領域的先進技術,推出多種規格、低CUT點、表面修飾、Lowα微米/亞微米球形硅微粉、高頻高速覆銅板用低損耗,新能源汽車用高導熱微米/亞微米球形氧化鋁粉等。

工信部數據統計,今年1-5月,國內規模以上電子信息製造業增加值同比增長13.8%;AI服務器的興起推動了PCB 需求的反彈,據TrendForce預測,2024年的HBM需求增長率近200%,2025年有望再翻倍。

針對公司應用於下游高頻高速覆銅板市場需求情況,今年4月,聯瑞新材在接收機構調研時表示,近年來,以HPC、AI和5G通信等需求增加,推動高頻高速覆銅板領域的發展,尤其是高速覆銅板領域,M6以上的高速覆銅板市場需求正在加快。

不過,也有市場分析認爲,國內供應先進封裝用的上游硅微粉行業內,中小型企業衆多,受產業政策推動,在市場需求不斷擴大的背景下,未來可能有更多的資本進入硅微粉行業,聯瑞新材將面臨更爲激烈的市場競爭,競爭加劇將導致行業整體盈利能力出現下降的風險。

《科創板日報》記者注意到,在市場需求增加的背景下,報告期內,聯瑞新材新增了兩期擴產項目,包括集成電路用電子級功能粉體材料建設項目、先進集成電路用超細球形粉體生產線建設項目。

其中,集成電路用電子級功能粉體材料建設項目進展方面,據連雲港新聞7月消息,目前該項目主體結構建設已完成,預計8月帶料調試,12月竣工投產,將形成年產2.52萬噸電子級功能粉體材料產品生產能力。

其他項目推進方面,根據公司半年報,報告期內,聯瑞新材高性能基板用高介電低損耗球形二氧化鈦開發項目、熱界面材料用氮化鋁開發項目、熱界面材料用氮化硼開發項目和先進封裝用亞微米球形硅微粉關鍵技術研發項目等進入工程化階段;超低損耗高速基板用球形二氧化硅開發項目已實現產業化並結題。