①そのうち2億元は1GWのスタッカブルモジュール製造プロジェクトに使用され、プロジェクトの計画建設期間は9ヶ月で、8,500万元は流動資金の補充に使用されます。②この企業の半分のN型TOPConバッテリー生産ラインは2024年上半期に稼働し、今回の募資プロジェクトではスタッカブル技術を採用しており、TOPConバッテリーの双極技術と良好にマッチしています。

《科創板デイリー》9月25日のニュース(記者:邱思雨)今日(9月25日)、時創エネルギーは増資案を公表しました。

公表によると、時創エネルギーは簡易手続きに従い、特定の対象者に対して株式を発行し、募集資金総額は2.85億元(本数を含む)を超えず、発行費用を差し引いた募集資金の純額は1GWのスタッカブルモジュール製造プロジェクトおよび流動資金の補充に使用され、発行対象者は35人(含まれる)。

そのうち、2億元は1GWのスタッカブルモジュール製造プロジェクトに使用され;8,500万元は流動資金の補充に使用されます。

そのうち、2億元は1GWのスタッカブルモジュール製造プロジェクトに使用され;8,500万元は流動資金の補充に使用されます。

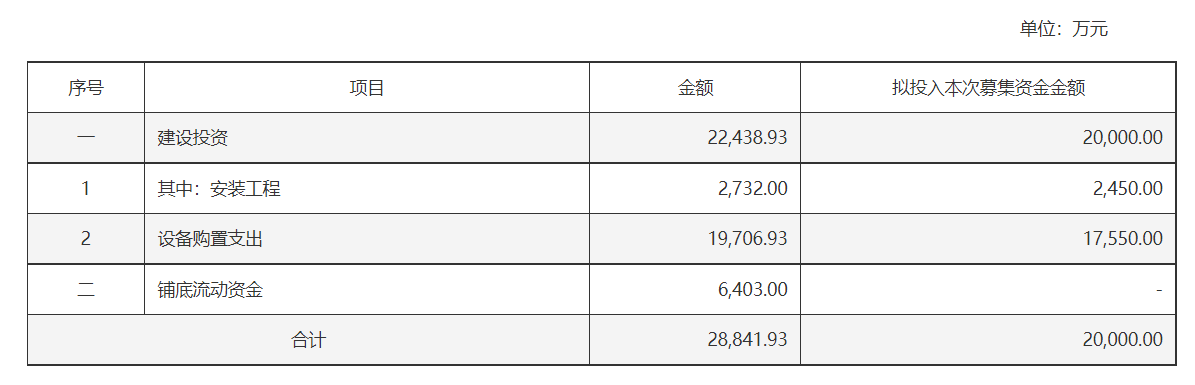

双極プロジェクトの総投資額は2.88億元で、プロジェクトの計画建設期間は9ヶ月で、プロジェクト完了後、年間1GWのスタッカブルモジュールの生産能力が増加します。このうち、今回の募集資金2億元は設備投資、機器購入費などを含む建設投資に使用されます。

時創エネルギーは、今回のスタッカブルモジュールプロジェクトを通じて、一方で、自社および顧客の組件プロセスの製造技術の困難点を適時に把握できるようになり、他方で、新製品の実際の量産データを取得し、研究開発センターが製品の改善を行い、研究開発サイクルを短縮することができます。

財務の面から見ると、時創エネルギーの当期純利益やキャッシュフローの状況は楽観的とは言えない。今年の上半期に、当該企業の親会社純利益は1.33億元の損失となり、前年同期の1.18億元の利益に比べて赤字になった。一方、営業活動によるキャッシュフローは-2.43億元の純額で、前年同期は-1.35億元であった。

業績面では、時創エネルギーは、太陽電池産業チェーン価格が全体的に下落気味であるため、太陽電池片の価格が急速に下落し、総合的な市場影響を受けて、同社の太陽電池の価格と販売量もそれに伴い減少し、売上高が減少したことを表明している。

光伏市場の「内部競争激化」により、太陽光発電各リンクのメーカーは、コスト削減と効率向上を模索している。

「グリッド線製造技術の進化は太陽光発電業界の注目ポイントの一つで、線が細くなるほど銀ペーストの使用量を減らし、それによってコストを削減し、同時に太陽電池片の遮光を減らし、発電効率を向上させるのに有利である。同社が自主開発したスタック型技術は、太陽電池表面の遮光問題を効果的に解決し、モジュールの変換効率を向上させるだけでなく、銀の消費を大幅に削減してコストを削減することができる。」時創エネルギーは述べています。

この数日前、時創エネルギーはtongwei co.,ltdと「技術協力開発契約」に署名し、双方はスタック型モジュール技術の技術協力開発と今後の量産計画の展開を計画しています。

この募集投資プロジェクトの実施により、時創エネルギーはスタック型モジュールの産業化を推進し、研究開発成果を量産ラインに移行させることになります。同社のハーフ切れN型TOPCon太陽電池生産ラインは2024年の上半期に投産されており、今回の投資プロジェクトに使用されるスタック技術は、TOPCon太陽電池の双POLO技術と良いマッチングを提供し、双POLO太陽電池内のPolyfingerによる光学損失を効果的に低減し、スタック技術の銀消費メリットを発揮することができます。

其中,2亿元用于年产1GW叠栅组件制造项目;8500万元用于补充流动资金。

其中,2亿元用于年产1GW叠栅组件制造项目;8500万元用于补充流动资金。