Commenced collaborative research aimed at establishing plastics material recycling technology.

Collaborating with academia, government, and industry to aim for a circular society using technology to "observe", "analyze", and "control" materials.

November 29, 2024

[Key Points of Announcement]

[Key Points of Announcement]

Tohoku University, National Institute of Advanced Industrial Science and Technology, Shiga Prefectural University, and Bridgestone Corporation have initiated a joint research project towards establishing material recycling technology for a type of plastic known as polyolefin (Note 1).

Overview

Tohoku University, National Institute of Advanced Industrial Science and Technology, Shiga Prefectural University, and Bridgestone Corporation have initiated a joint research project towards establishing material recycling technology for a type of plastic known as polyolefin.

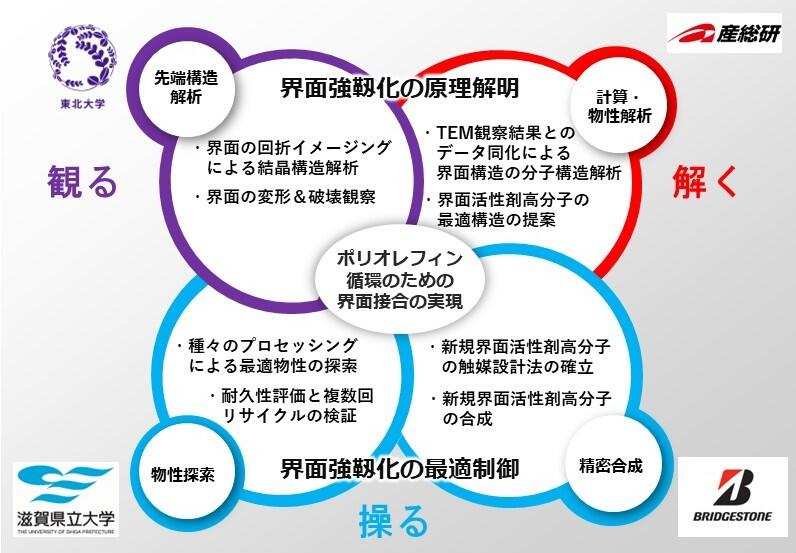

In this project, the aim is to establish guidelines for the development of a new resource-circulating polyolefin material that can be repeatedly recycled using technology to "observe" polyolefin under an electron microscope, "analyze" its molecular structure, and "control" the synthesis of materials with optimal properties using various methods.

【Details】

Background of the study

Currently, out of the waste plastics generated domestically, only 7.17 million tons are being effectively utilized, with a material recycling rate of 22%. The proportion of raw materials in waste plastics is mainly composed of polyolefins such as polyethylene and polypropylene, accounting for more than half of the situation. (Note 2)

In addition, waste plastics are composed of various compounds (impurities) mixed together, making their separation extremely difficult, resulting in their current state of being recycled in a mixed condition. On the other hand, recycled plastics have a weak bonding force with impurities, making them prone to breakage when recycled in a mixed state. This limits the range of uses for recycled products. To further accelerate the material recycling of plastics, technology is needed to produce high-strength recycled materials by mixing them without separating impurities.

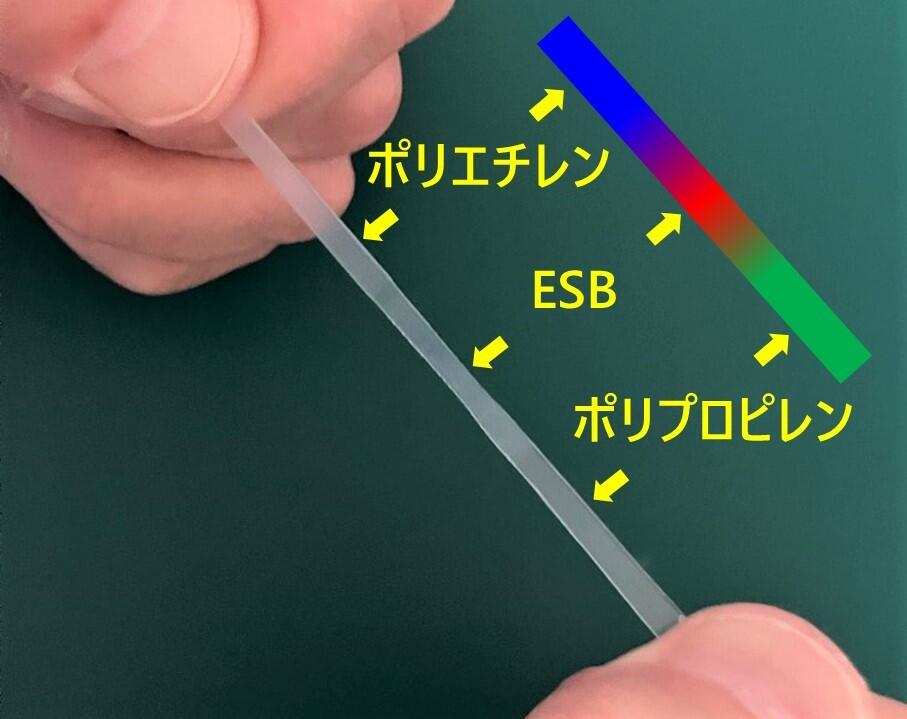

This Initiative

In response to this situation, Bridgestone has discovered that by adhering a Japan-developed high-functionality ethylene-based thermoplastic elastomer (ESB) at the interface (boundary) of polyethylene and polypropylene, which have a high composition ratio in waste plastics, the interface is strengthened and the adhesion significantly improves. In this study, the mechanism of the change in polyolefin properties by ESB is elucidated at the molecular level, and the optimal molecular design of ESB is carried out to enhance the strength of recycled materials using polyethylene and polypropylene, aiming to improve their quality and increase added value. This will explore the potential for achieving effective material recycling of plastics.

This project was adopted in the 2024 Fiscal Year Strategic Innovation Research Promotion Project (CREST) in the research area "Creation of Innovative Fusion Basic Technologies for Materials Creation and Circular Processes" operated by Japan Science and Technology Agency (JST).

Research Theme: Development of Interfacial Toughening Technology for the Circularity of Polyolefin Society

Research Representative: Hiroshi Jinnai, Professor, Institute for Materials Research, Tohoku University

Research Period: October 1, 2024 - March 31, 2030

Tohoku University will 'observe' the strengthening of bonds at the nano level of polyolefins using electron microscopy. AIST will 'solve' the reasons for ESB bonding to polyolefins from molecular structures. Shiga Prefectural University will effectively manipulate ESB, while Bridgestone will synthesize ESB with optimal properties, taking on the role of 'control'. By cycling through these 'observe', 'solve', and 'control' steps, continuously providing feedback to each other, the aim is to establish guidelines for the development of new resource-circular polyolefin materials capable of repetitive material recycling.

【Glossary】

- Note 1. Polyolefin: a type of plastic, non-toxic, excellent durability, lightweight, inexpensive, easy to process, and has many other characteristics, so it is used in a wide range of applications. Includes polyethylene and polypropylene.

- Note 2. For information on the recycling status of waste plastics, please refer to the following.

In 2022, the total amount of waste plastics was 8.23 million tons, with an effective utilization rate of 87%. The situation of production, disposal, recycling, and treatment of plastic products (material flow diagram) is disclosed by Plastic Information Center, Japan Plastics Resource Recycling Association. - Note 3. Bridgestone has successfully developed a new material for the first time in the world, which takes the initials of the constituent components ethylene, styrene, and butadiene. It has many functions such as high strength, high elasticity, excellent puncture resistance, simple self-repair, and high adhesion with different materials, while utilizing the versatility of ethylene and combining it with styrene and butadiene. It is also a high value-added material contributing to the reduction of environmental impact substances, and its originality and ripple effects have been recognized. It also won the 2024 Polymer Society Technical Award.

Polymer Society Technical Award | Japan Polymer Society

For inquiries about this matter, please contact

【Contact Information】

(Regarding research matters)

Tohoku University Institute of Multidisciplinary Material Sciences

Professor Hiroshi Jinnai

TEL: 022-217-5329

Email: hiroshi.jinnai.d4@tohoku.ac.jp

(Regarding press inquiries)

Tohoku University Institute of Multidisciplinary Material Sciences Public Relations Information Office

TEL: 022-217-5198

Email: press.tagen@grp.tohoku.ac.jp

National Institute of Advanced Industrial Science and Technology

TEL: 029-862-6216

Email: hodo-ml@aist.go.jp

Business Planning Division, University of Shiga Prefecture

TEL: 0749-28-8506

Email: keiei_kikaku@office.usp.ac.jp

Bridgestone Corporation Domestic Public Relations Division

TEL: 03-6836-3333

above

【発表のポイント】

【発表のポイント】