Dai Nippon Printing Co., Ltd. (hereinafter referred to as DNP) has been providing the "DNP Factory Support Service Meglus Port" since 2023, which supports digital transformation (DX) in manufacturing sites such as factories. This time, a sensing module for "conveying parts" used in PET bottle filling lines has been added utilizing unique DX and automation technologies. This module enables the quantification of the state of the "conveying parts" in PET bottle filling lines, which was previously difficult, leading to improved measurement and maintenance operations, thereby reducing the burden of managing and maintaining production facilities.

DNP has achieved the No. 1 share in Japan for the "Aseptic Filling System for PET Bottles" and has 190 installations both domestically and internationally. Based on these achievements, the sensing services related to conveying parts for PET bottle filling lines have been expanded, and operations at beverage manufacturers began in November 2024.

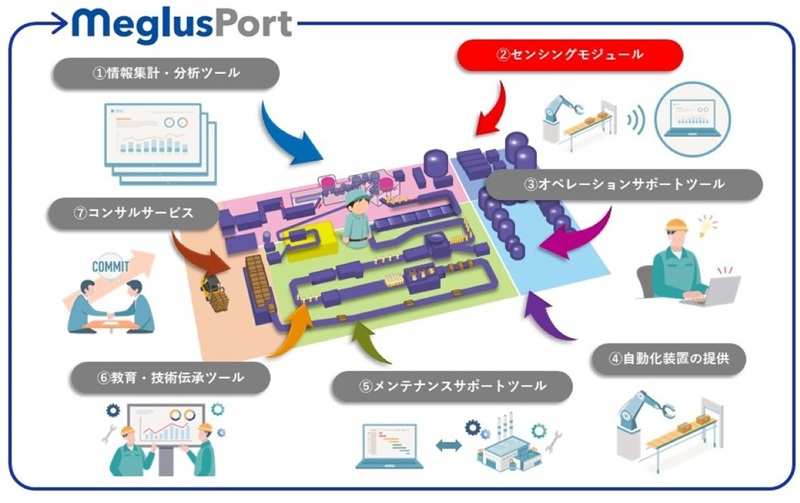

An overview image of the "DNP Factory Support Service Meglus Port" and the functions expanded this time.

[Background of Function Expansion]

In recent years, particularly in Japan, issues such as labor shortages due to declining population and challenges in human resource development have become serious, with beverage and food manufacturers also striving to address these issues. In manufacturing factories, it has become urgent to promote DX to automate tasks, improve productivity, and enhance employee engagement.

In recent years, particularly in Japan, issues such as labor shortages due to declining population and challenges in human resource development have become serious, with beverage and food manufacturers also striving to address these issues. In manufacturing factories, it has become urgent to promote DX to automate tasks, improve productivity, and enhance employee engagement.

To address these challenges, DNP has developed a sensing module that newly installs Sensors in production equipment, making it possible to quantify the condition of production equipment, which was previously difficult. By coordinating with the "Information Aggregation and Analysis Tool" already provided for managing and analyzing production line data, more accurate equipment management can be achieved. This leads to a reduction in the burden of data analysis for employees and the expansion of effects, contributing to improved operational efficiency and labor savings.

[Features of Meglus Port with Expanded Sensing Modules]

- This service can be utilized for automatic measurement of the grippers (devices for grasping and holding objects) of molding and filling machines, behavior analysis of label transport, bottle topple analysis on conveyors, and measurement, visualization, and analysis of the condition of not only PET bottle filling lines but all production facilities and packaging materials.

Image of the gripper of molding and filling machines.

- By utilizing the sensing module, automatic measurement of the position and operational status of the grippers of PET bottle molding and filling machines can be conducted, allowing for preventative maintenance to avoid damage from the molding of PET bottles.

- In the aseptic filling system for PET bottles, hundreds of grippers are used. Previously, it was necessary to manually measure each gripper's position within 0.01mm during maintenance. By utilizing the developed sensing module, the sensor can timely identify areas that need correction, allowing maintenance to be performed only on the relevant parts. This significantly reduces the workload of daily dimension measurement tasks for grippers, enabling approximately 90% time reduction compared to before implementation (according to our investigation).

- This service was adopted by a beverage manufacturer in November 2024. It is being utilized for monitoring and analyzing the behavior of label transport in the PET bottle filling line, as well as for measuring and maintenance tasks for the important grippers in PET bottle molding and filling machines.

[Future Developments]

DNP is offering the expanded "DNP Factory Support Service Meglus Port" for beverage and food manufacturers, aiming to implement it in 50 lines by 2030. Additionally, the functions and menus of this service will also be enhanced, including operation support tools, automation equipment, maintenance support tools, Mainland Education tools, and Consulting Services.

*1 About DNP factory support services →

*2 About the aseptic filling system for PET bottles →

* The company and product names mentioned are trademarks or registered trademarks of their respective companies.

■ About Studio Veronica Ditting.

近年、国内では特に、労働人口減少による人手不足や人材育成の課題が深刻化しており、飲料・食品メーカーでもこうした課題の解決に努めています。製造工場においても、DXの推進による作業の自動化や生産性の向上、従業員のエンゲージメントを高める取り組みが急務になっています。

近年、国内では特に、労働人口減少による人手不足や人材育成の課題が深刻化しており、飲料・食品メーカーでもこうした課題の解決に努めています。製造工場においても、DXの推進による作業の自動化や生産性の向上、従業員のエンゲージメントを高める取り組みが急務になっています。