Mitsubishi Chemical Group (hereinafter referred to as "the Company Group") has decided to increase the production capacity of synthetic quartz powder "Mitsubishi Synthetic Quartz" (hereinafter referred to as "the Product"), which is used in semiconductor manufacturing processes, at the Kyushu Plant, Fukuoka area (Kita-Kyushu City, Fukuoka Prefecture). Operations are planned to commence in September 2028.

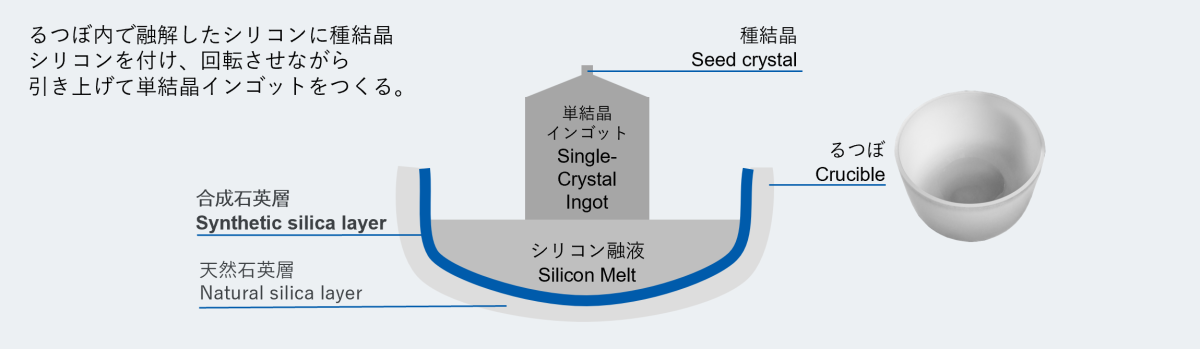

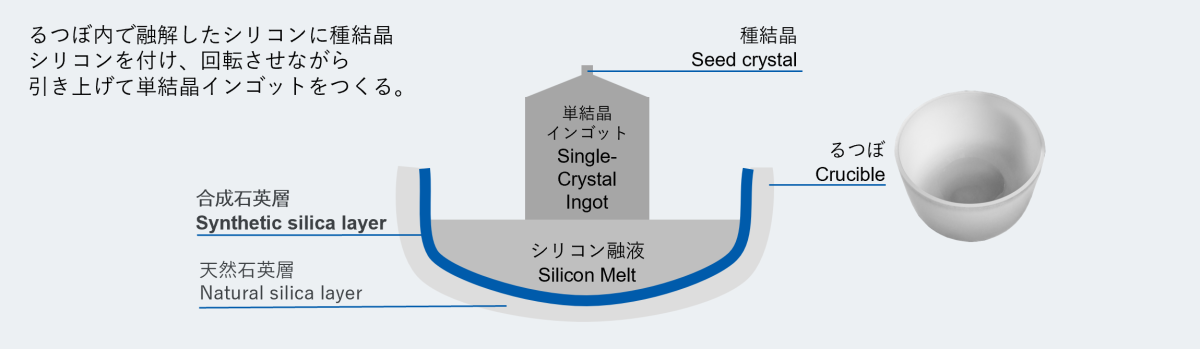

The Product is a synthetic quartz powder characterized by ultra-high purity and is used as a raw material for "quartz crucibles" used in the production of semiconductor silicon (hereinafter referred to as "ingots") and high-purity quartz parts within semiconductor manufacturing equipment.

In particular, during the ingot manufacturing process, to suppress the contamination of impurities that significantly degrade wafer quality, the surface of the quartz crucible requires extremely high purity. This Product boasts high competitiveness in this application by achieving world-class purity as sand-like silica through manufacturing technology cultivated over many years.

To respond to the demand associated with the continuous growth of the semiconductor market, the decision to enhance production capacity has been made.

・Location: Mitsubishi Chemical Corporation Kyushu Plant, Fukuoka area (1-1 Kurosaki Joishi, Yahatanishi Ward, Kita-Kyushu City, Fukuoka Prefecture)

・Commencement of operations: September 2028 (planned)

・Production capacity: Current production capacity + 35%

Mitsubishi Synthetic Quartz

Image of use in a crucible

Our group offers a variety of materials and services in the Semiconductor Device manufacturing process and will continue to contribute to the Semiconductor industry by providing high-quality and stable supply.

About Mitsubishi Synthetic Quartz

Introduction site for Semiconductor related products and services of Mitsubishi Chemical Group

The Product is a synthetic quartz powder characterized by ultra-high purity and is used as a raw material for "quartz crucibles" used in the production of semiconductor silicon (hereinafter referred to as "ingots") and high-purity quartz parts within semiconductor manufacturing equipment.

In particular, during the ingot manufacturing process, to suppress the contamination of impurities that significantly degrade wafer quality, the surface of the quartz crucible requires extremely high purity. This Product boasts high competitiveness in this application by achieving world-class purity as sand-like silica through manufacturing technology cultivated over many years.

To respond to the demand associated with the continuous growth of the semiconductor market, the decision to enhance production capacity has been made.

・Location: Mitsubishi Chemical Corporation Kyushu Plant, Fukuoka area (1-1 Kurosaki Joishi, Yahatanishi Ward, Kita-Kyushu City, Fukuoka Prefecture)

・Commencement of operations: September 2028 (planned)

・Production capacity: Current production capacity + 35%

Mitsubishi Synthetic Quartz

Image of use in a crucible

Our group offers a variety of materials and services in the Semiconductor Device manufacturing process and will continue to contribute to the Semiconductor industry by providing high-quality and stable supply.

About Mitsubishi Synthetic Quartz

Introduction site for Semiconductor related products and services of Mitsubishi Chemical Group