JTEKT Corporation (Headquarters: Kariya City, Aichi Prefecture, President: Yoshito Kondo, hereinafter referred to as "JTEKT") and its group companies, JTEKT Thermo System Corporation (hereinafter referred to as JTEKT Thermo System) and JTEKT Fluid Power System Corporation (hereinafter referred to as JTEKT Fluid Power System), received the "Chairman's Award of the Energy Conservation Center" in the Energy Conservation Award Product and Business Model category for the 2024 fiscal year (Reiwa 6).

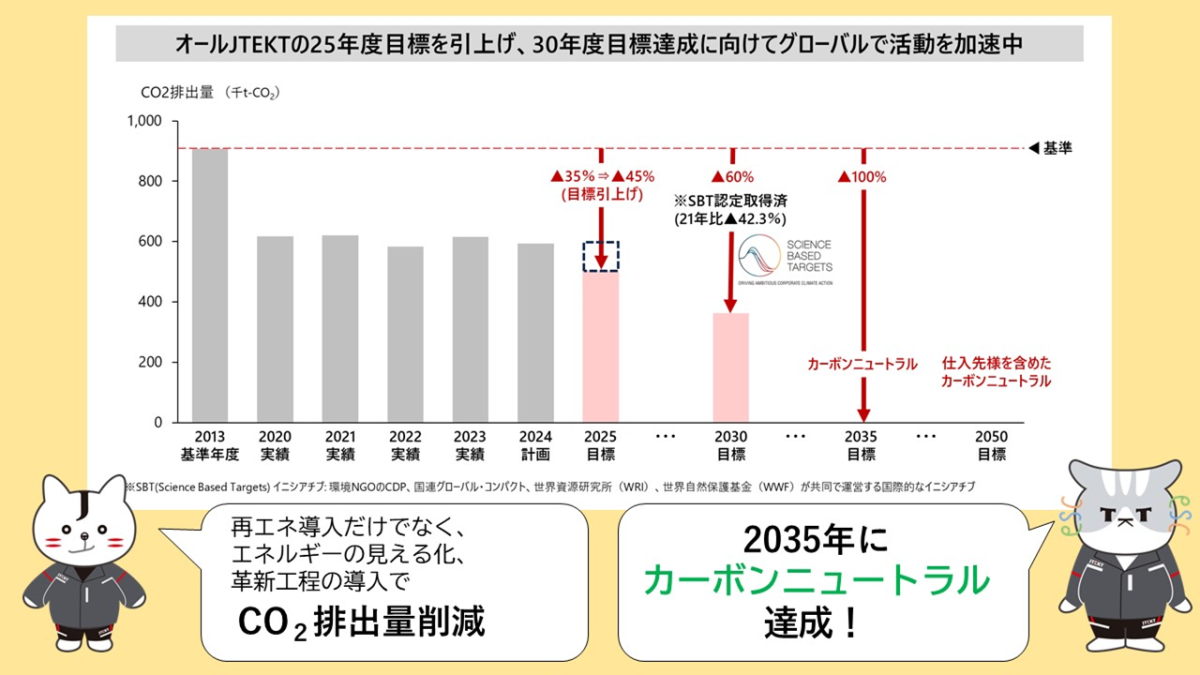

The JTEKT Group has established "Environmental Challenge 2050" and continues to take on challenges under the slogan "All for One Earth" to connect our irreplaceable planet to future generations. To achieve Carbon Neutrality, efforts are being made to reduce CO2 emissions in all SCOPE areas 1, 2, and 3, aiming for Carbon Neutrality in SCOPE 1 and 2 related to its production activities by 2035.

In this energy conservation award, not only the company’s reduction of CO2 emissions but also the products of JTEKT Group companies that contribute to CO2 emissions reduction in various industries were evaluated, with both companies receiving the award.

2024 Energy Conservation Award - Chairman's Award of the Energy Conservation Center

JTEKT Thermo System: "CN Retrofit Service for Metal and Industrial Heating Equipment"

The thermal processing of Metal generates a significant amount of CO2 emissions, with 24 million tons of CO2 emitted from industrial furnaces in Japan in 2022. The average lifespan of industrial furnaces is about 30 years, making energy-saving measures utilizing existing furnaces urgent.

The awarded "CN Retrofit Service for Metal and Industrial Heating Equipment" contributes to the reduction of CO2 emissions from currently operating furnaces.

- Super Moldasarm

Conventionally, the insulation layer of the heating chamber uses insulating bricks and insulating boards. By replacing these insulating bricks and boards with the newly developed Super Moldasarm made from a unique material and method, thermal insulation is improved, and a reduction of about 20% in standby power consumption compared to conventional methods is expected. (In the case of an empty furnace at 930℃) - QEC (Quenching oil temp Eco Control)

Heat treatment equipment with a quenching oil tank typically needs to maintain a constant oil temperature until the next quenching. Traditionally, the quenching oil is forced to cool after quenching and is heated for a short period by heaters to keep a constant temperature, but the method has been optimized to gradually cool down without forced cooling until the next quenching timing. This is expected to reduce the power consumption of heaters used to maintain oil temperature by about 50% compared to conventional methods. (Setting temperature at 90℃) - N2 Shot

In gas carburizing furnaces, when the doors are opened and closed for product loading and unloading, a negative pressure can occur inside the furnace or oil tank, posing a risk of explosion due to the intake of unburned air. Therefore, a large flow of reforming gas is continuously introduced into the heat treatment furnace to prevent negative pressure, but during stable pressure conditions other than when the doors are opened, the amount is excessive. Thus, the amount of reforming gas is always kept at a low flow, and N2 gas is introduced at the timing when the internal pressure becomes unstable, which can reduce the amount of reforming gas by about one-third compared to conventional methods, resulting in a reduction in the energy consumed for gas generation.

2024 Energy Conservation Grand Prize - Chairman's Award from the Energy Conservation Center

2024 Energy Conservation Grand Prize - Chairman's Award from the Energy Conservation Center

JTEKT Fluid Power System 'Ultra Low Power Electromagnetic Switching Valve HD1E Series'

To reduce CO2 emissions in the Manufacturing sector and achieve Carbon Neutrality, energy-saving measures for production equipment are the most effective. The awarded "Ultra Low Power Electromagnetic Switching Valve HD1E Series" is an electromagnetic switching valve installed in production equipment, achieving greater energy savings than conventional products and contributing to Carbon Neutrality in Manufacturing.

By restructuring the magnetic circuit configuration, losses in the magnetic circuit have been reduced, and by reviewing the suction surface shape of the plunger, excessive suction force has been minimized. Through these two measures, necessary suction force is secured while achieving a reduction of approximately 30% in the power consumption of the electromagnetic switching valve body. Additionally, the product weight has been reduced by 8% through shape reconsideration and other actions.

Looking ahead.

The Jayecct Group, as a solution provider, will not only focus on the awarded products but also provide solutions that contribute to reducing CO2 emissions in all industries in addition to reducing its own CO2 emissions.

By leveraging the competencies of the Jayecct Group and co-creating by connecting internal and external competencies, we will provide Only One solutions and contribute to the earth, society, and our customers.